Terminology

CERAMIC TILES: Ceramic tiles (or tiles) are artificial material, with raw material clay used from antiquity until today for lining floors, walls and for decoration. It is unknown when man first used ceramic tiles. Surfaces paved with ceramic tiles have been found in pyramids, in ancient Babylon with elaborate representations and colors and in all ancient Greek and Roman cities. During the Middle Ages they were widely used in the Islamic states, mainly in Persia and Syria, with elaborate decorations. The Moorish conquerors of Spain were the first to bring them and spread them in Europe. In general use they were first used in Spain, Portugal and Italy and today almost all over the world. In the 15th century tiles with a production center in Seville were exported to Britain and Italy. In Italy, buildings in Naples and Genoa decorated with Seville ceramics are still preserved today.

In 1840, their widespread use was reported in paving houses in southern Spain, with Andalusia as their construction center, and a mechanical method was used for the first time. In 1888 they were presented at the Barcelona International Exhibition. In 1980 in Italy appeared a new method of construction and baking, MONOCOTTURA as it is called, which brought a revolution in the field. With this method, the clay and the clay were baked together at the same time, reducing the preparation time and making them more durable. It also reduced production and manufacturing costs by allowing them to be sold at more affordable prices.

The first tiles were hand-painted, made of clay and baked in the sun or baked on fire and also cut by hand. Today they are widely used because of their very good technical characteristics of their easy installation in relation to marble but also because of the lower cost of it. They are manufactured in many dimensions (up to 120x180cm) and colors. They are resistant to all weather conditions and are used in the paving of interior floors, in the paving of sidewalks, lining of bathrooms, kitchens and walls as decorations. Ceramic tiles are divided into those that are coated with porcelain (smaltato) and are more glossy.

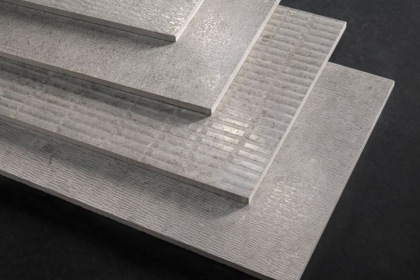

In those that do not have porcelain coating, mats as they are called, and in exterior tiles with embossed face (strutturato - grip - bocciardato) so that it does not slip. Depending on the intended use, they have different thickness (spessore) and strength. The raw material today is clay that is baked at high temperatures and liquid clay, its coloring and all their construction is done mechanically. UNI technically determines the ceramic tile that has a water absorption coefficient of less than 0.5% (UNI EN ISO 176 BI) (source Wikipedia.org)

MONOCOTTURA: In 1980 in Italy appeared a new method of construction and baking, MONOCOTTURA as it is called, which brought a revolution in the field. With this method, the clay and the clay were baked together at the same time, reducing the preparation time and making them more durable. It also reduced production and manufacturing costs by allowing them to be sold at more affordable prices. The first tiles were hand-painted, made of clay and baked in the sun or baked on fire and also cut by hand.

Today they are widely used because of their easy installation in relation to marble and for reasons of economy since their selling price is much lower than that of marble. They are made in many dimensions and colors. They are resistant to all weather conditions and are used in the paving of interior floors, in the paving of sidewalks, lining of bathrooms, kitchens and walls as decorations. Ceramic tiles are divided into those that are coated with porcelain and are more glossy.

In those that do not have porcelain coating, mats as they are called, and in exterior tiles with embossed face so that it does not slip. Depending on the intended use, they have different thickness and strength. The raw material today is clay that is baked at high temperatures and liquid clay, its coloring and all their construction is done mechanically. Their construction today is done in the following way: first the materials are poured in liquid form into molds and dried, then they are coated and put in ovens where they are baked at temperatures of 2,000 degrees and above. (source Wikipedia.org)

BICOTTURA: The term refers to the technique of producing ceramic tiles. The tiles characterized by this term have been produced by double firing. In the first phase, the tile biscuit is baked and after the enameling is done, it is baked again to melt the enamel powder and to be glazed. (source Wikipedia.org)

FULL BODY: In tiles the term refers to the uniform mass of the material. This way of construction gives the tiles high strength and mechanical properties. The mass of the tile is pressed at very high pressures and baked at temperatures that often exceed 1700 ° C.

GRES PORCELLANATO: A porcelain tiles (granite tiles) are produced by the process of agglomeration of clay ceramics, with star, kaolin and quartz sand. The raw materials are first crushed, granulated, converted into pulp and compressed with high-pressure presses. This is followed by baking which takes place at a temperature above 1250 ° C in ovens up to 140m long, where the raw material gradually comes to the maximum temperature, is kept there for about 25-30 minutes, and gradually always cools to room temperature.

The baking process causes the glazing of the mass, giving the typical characteristics of strength, tightness and longevity. During baking, various deformations occur. The size reduction after baking can reach up to 7%, for very large dimensions (60x60cm, 120x120cm) it is usually adjusted after baking.

After baking, the tiles go through quality control and are divided into categories according to the percentage of defects, the caliber and the tone. Material that does not fully comply with the parameters dictated by UNI is classified into (commercial, 2nd, 3rd sorting, etc.). With the existing production technologies, tiles can be produced with sizes ranging from 5x5cm up to 180x180cm, with a thickness from 3 to 22mm. (source Wikipedia.org)

Α’ SELECTION: We call the first sort the best possible quality during the production of a tile which is subject to international standards according to UNI, ISO, DIN. Based on these international standards, the tiles are categorized and the deviations during the production process are delimited. When the deviations are greater than the allowed ones then and depending on the extent and the percentage of these deviations the material falls into another quality category lower than A '. As such we refer to the commercial sorting, B ', C' etc.

PASTA COLORATA: The porcelain mixture can also be colored during the mashing phase and so the final product is called pasta colorata with excellent characteristics for both private and public use.

RETTIFICATO: Technical treatment which is applied after the production of the tile at its edges and aims to minimize the tolerances of its dimensions. During this treatment, the tile is cut (shaved) vertically on all its sides, which results in the possibility of placing it without a joint. The surfaces on which reticular tiles are placed give a uniform and homogeneous result. This makes it possible to use large or very large tiles in small areas with a significant upgrade of the aesthetics of these spaces.

TECHNOGRANITE : Technogranite or Artificial Granite is a synthetic quartz rock used as a decorative material in buildings. Technogranite is made with the same materials as technomarble, ie it is a visible colored mortar reinforced with polyester resins. It has high hardness and is very durable, with minimal absorbency, while it does not need the maintenance of a natural material. In relation to artificial marble it is produced in slabs of specific dimensions, not in volumes and in a wide variety of colors. It is used in constructions mainly in wall cladding, in kitchens, fireplaces and rarely in flooring. (source Wikipedia.org)

GRANITE: Granite is a widespread, natural igneous, plutonium rock with granular tissue and acidic texture with high hardness. It belongs to the plutonium igneous rocks because it was created by the solidification and crystallization of magma inside the crust at great depth, so it has an all-crystalline, granular tissue. In fact, its name comes from the Latin word granum, meaning grain and is due to its granular texture.

A plutonium rock, in order to be classified as granite, must contain stars (alkaline stars and plagioclase) and quartz, but usually, in addition to the mandatory components, granites contain ferromagnesium minerals (mica, amphibians, etc. ) and syndromes, (zirconia, apatite, titanite, etc.). Its texture also determines its color. It is mainly used as a decorative material in buildings. (source Wikipedia.org)

THE TERM GRANITE WITH WHICH NEWLY TECHNOLOGICAL TILES ARE DESCRIBED TO DECLARE THEIR HIGH MECHANICAL STRENGTH, THEY HAS NO ABSOLUTE ABOUT THEM. THE TERM GRESPORCELLANATO IS MOST SUITABLE FOR THE DESCRIPTION OF THESE TILES.